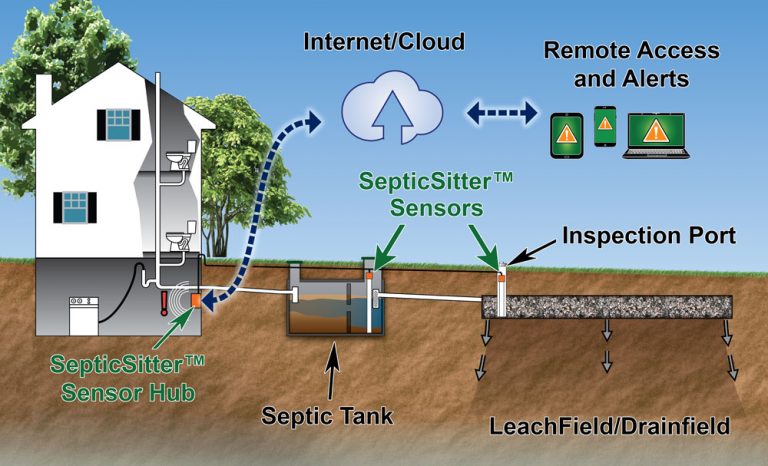

SepticSitter is a septic monitoring and early-warning system for onsite sewage systems. Non-contact sensors easily install in septic, pump tanks and drain fields, preventing hazardous system overloads. Real-time measurements are displayed in an online dashboard, historical data is stored for informed proactive maintenance and decision making.

How it Works

Get familiar with how SepticSitter monitors any type of septic system.

Introduction

Breakdown

The three main components of a SepticSitter system are:

Non-Contact Ultrasonic Sensors

Sensors are connected in a daisy-chain, end-to-end configuration using a single string of direct-bury rated, CANBUS power/communications cables.

Hub (gateway)

Cconnects one or more sensors to the internet via ethernet or mobile network connection

Web Application

Configurable graphs for display and manipulation of sensor data, a flexible alert system, and a tiered, user-management system.

Application

SepticSitter sensors are connected in a daisy-chain, end-to-end configuration using a single string of direct-bury rated, CANBUS power/communications cables. The liquid level measurement range is currently from 4 inches (0.10m) to 6.5 feet (2.0m). A custom CAN BUS bootloader enables remote firmware updates of the sensors in the field.

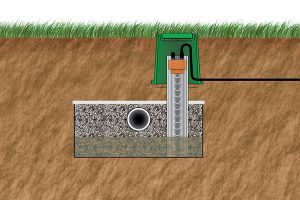

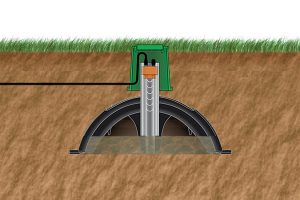

Sensors are mounted on a nominal 2” (50mm) PVC pipe and determine liquid levels in tanks and drain fields using non-contact, time-of-flight (ToF) measurements. An IR temperature sensor corrects for variations in the speed of sound through air and also allows monitoring of system temperatures. Readings can be configured to occur at a range of time intervals, typically every 5 to 30 minutes, 24/7.

Sensors are mounted on a nominal 2” (50mm) PVC pipe and determine liquid levels in tanks and drain fields using non-contact, time-of-flight (ToF) measurements. An IR temperature sensor corrects for variations in the speed of sound through air and also allows monitoring of system temperatures. Readings can be configured to occur at a range of time intervals, typically every 5 to 30 minutes, 24/7.

SepticSitter Retrofits To All Types Of Leachfields: Stone, Chambers, EZflow®, Eljen...

... and Also Installs In Septic Tanks, Pump Tanks & Cesspools

• Non-contact ultrasonic sensors won’t get “hung up” or fouled

• Sensors install and retrofit easily – tanks, leachfields and cesspools.

• Sensor Hub connects to existing internet service at home/business

• Cellular internet option available

• View continuous profile of liquid levels from any connected device

• Customizable, warnings, alerts & notifications

• Low voltage, direct-bury power/communication cables

• Non-contact ultrasonic sensors won’t get “hung up” or fouled

• Sensors install and retrofit easily – tanks, leachfields and cesspools.

• Sensor Hub connects to existing internet service at home/business

• Cellular internet option available

• View continuous profile of liquid levels from any connected device

• Customizable, warnings, alerts & notifications

• Low voltage, direct-bury power/communication cables

SepticSitter provides Benefits on Multiple Levels

Early Detection of Potential Issues...

• Septic tank effluent filter plugging

• Drain field hydraulic overloading

• Drain field organic overloading

• Leaking plumbing fixtures

• Excessive clogging of infiltrative surface

• Groundwater infiltration

• Neglected maintenance

• Drain field hydraulic overloading

• Drain field organic overloading

• Leaking plumbing fixtures

• Excessive clogging of infiltrative surface

• Groundwater infiltration

• Neglected maintenance

Valuable System Information...

• Instantaneous liquid levels

• Historical trends and data logging

• Proof of drainfield recovery

• Dry trenches – under-utilized drainfield areas

• Historical trends and data logging

• Proof of drainfield recovery

• Dry trenches – under-utilized drainfield areas

General Management Guidance...

• Alternating, dosing and resting systems

• Uneven zone distribution

• Sewage system expansion

• Uneven zone distribution

• Sewage system expansion

Easy to Install and Retrofit...

• Fits industry standard inspection ports (observation ports)

• Can be completely buried if desired

• Simple set-up and configuration

• Low voltage power

• Can be completely buried if desired

• Simple set-up and configuration

• Low voltage power

Peace of Mind for Your Behind ™

Check out the live demo of our cloud access site with real system data from our On-site Testing System.