Sara Heger, Ph.D., wrote a great article for Onsite Installer Magazine summarizing the benefits of pressure distribution. A paper by Bridson-Pateman et al (2013) out of Dalhousie University (Halifax, NS) compared performance under gravity-fed versus periodically dosed (twice per day) loading conditions and found performance benefits with dosed systems versus gravity. Here is a quote from the abstract for the paper titled: The Effects of Dosed versus Gravity-Fed Loading Methods on the Performance and Reliability of Contour Trench Disposal Fields Used for Onsite Wastewater Treatment.

Pressure dosed septic drainfields have improved hydraulic performance

SepticSitter™ collects the data to prove it

In this study, two identical contour trench disposal fields were monitored for 3 yr to compare performance under gravity-fed versus periodically dosed (twice per day) loading conditions. Ponded water depths in the distribution trench of the gravity-fed disposal field were observed to increase steadily during the monitoring period, indicating progressive clogging. This was not observed in the periodically dosed field. This study demonstrated adequate treatment of residential wastewater by contour trench disposal fields regardless of loading method. However, because the hydraulic performance of these systems is heavily dependent on pretreatment and loading methods, it is recommended that a dosing system be used to distribute wastewater to contour trench disposal fields to help prevent hydraulic failure.– Bridson-Pateman, et al (2013)

Construction of shallow pressure dosed trench (courtesy David Meints).

Maximum trench ponding levels difficult to detect in pressure dosed systems using manual observation methods

The Bridson-Pateman study involved the use of a dosing apparatus, rather than a pump for full pressure distribution, however the benefits over gravity trickle fed distribution were still significant. The authors noted that biomats within both systems developed progressively, and that ponding of effluent was observed in the distribution trench of both systems. However, ponded water was only observed sporadically in the distribution trench of the dosed system. The authors state that "This is potentially due to sampling strategy; the dosed system was dosed only twice daily, so observations were influenced by the time difference between the sample collection and the last dosing event."

This is a significant limitation of manual observation methods where site visits to check on ponding levels are unlikely to coincide with maximum levels for the day/week/month. With humans collecting the data, its "hit or miss". As a result, those trying to get a true picture of what is going on underground will likely be missing critical data points.

This is a significant limitation of manual observation methods where site visits to check on ponding levels are unlikely to coincide with maximum levels for the day/week/month. With humans collecting the data, its "hit or miss". As a result, those trying to get a true picture of what is going on underground will likely be missing critical data points.

SepticSitter sensors provide a true picture of pressure dosed trench levels

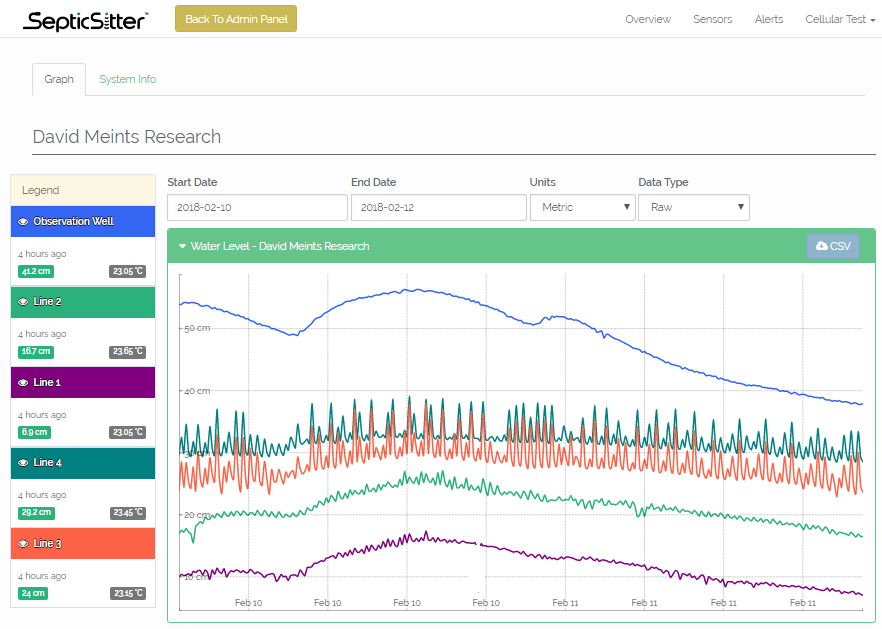

David Meints, P.E., of Meinco Wastewater was in that situation when he was trying to understand what was going on with a shallow pressure dosed drainfield receiving secondary treated effluent. Meints was making site visits every two weeks to check ponding levels in the four shallow pressure trenches and an upslope monitoring well. He had suspicions about what was going on, but didn't have enough data to confirm his theories. He retrofitted SepticSitter to monitor ponding levels in all the trenches and also in the monitoring well. With the SepticSitter sensors taking readings every 10 minutes, Meints now had all the data he needed to get a true picture of how the trenches were responding to dosing events (see graph below).

Not surprisingly, the data confirmed that baseline ponding levels were higher in the trenches farther down the slope. He also noticed how trench effluent levels were influenced by rainfall events, and how they kept closely in sync with fluctuating groundwater table levels.

Not surprisingly, the data confirmed that baseline ponding levels were higher in the trenches farther down the slope. He also noticed how trench effluent levels were influenced by rainfall events, and how they kept closely in sync with fluctuating groundwater table levels.

SepticSitter web application showing two days worth of raw level data in pressure dosed trenches and observation well (blue line) of David Meints' system. Sensors were taking readings every 10 minutes.

Automatic distributing valves assist with resting between doses

The use of automatic indexing or distributing valves (eg. KRain 6000 series Hydrotek or Orenco, Clarus 6000 series valves) are also a great way to ensure resting periods between doses and allow time for the soil to recover. For commercial systems, these valves allow engineers to design modular drainfields which can be easily expanded without having to change any of the pumping system equipment or controls. The IVM6000™ Intelligent Valve Monitor can be used with these valves to ensure reliability by providing an immediate alert at the control panel in the event of a valve malfunction.

The IVM6000™ Intelligent Valve Monitor (by Dynamic Monitors) installs easily on 6000 series indexing valves by KRain, Orenco, Clarus.

Comment